|

|

|

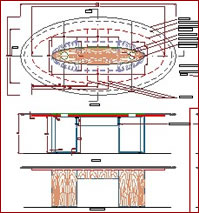

CAD Working Drawings

|

|

Sliding Table Saw

CNC Router

Outside of the Shop

|

|

Millwork Shop

|

|

ABOUT US: ABOUT US:

We are 12 self-motivated individuals from divergent backgrounds, who

share a passion for fine woodworking. The majority of our craftsmen

have at least 15 years of personal hands-on experience as woodworkers

and furniture makers, most of that tenure acquired in our shop. We

value the benefits of integrating traditional woodworking methods with

modern materials, hardware, machinery, tools and computer software. An

emphasis is placed on the sharing of skills and techniques, with the

goal being that any craftsman will be proficient enough to accomplish

any given task that may come along. This environment encourages the

co-operative teamwork essential to timely completion of larger

commercial projects. [Read

about how Woodpecker was formed]

DESIGN DEVELOPMENT & PRICE QUOTATIONS DESIGN DEVELOPMENT & PRICE QUOTATIONS

Beginning with the first conversation about a client’s needs, we

start a process of imagining creative solutions. We work with you to

formulate concepts of finished furniture pieces, accounting for

function, style, materials, cost and schedule. We use an extensive and

reliable network of resources for the wide range of materials and

technologies used in furniture making. After getting “the big

picture,” we may offer specific suggestions or details that might

enhance the developing design. Absent a sketch, we will produce a

preliminary computer drawing with enough detail to develop an accurate

written proposal and price quotation. Upon acceptance of our proposal,

we refine the initial drawing into a set of detailed CAD working drawings in large scale from which the

furniture will be built.

VENEERING & WOODWORKING VENEERING & WOODWORKING

We are often asked if we can build a piece of furniture in “solid

wood”. Of course we can, we cut our teeth building solid hardwood

furniture and always look forward to building a fine piece of solid

wood furniture. But the real skill in furniture making lies in the

ability to harness the exquisite beauty of matched patterns in wood

only available by using veneer. Through the use of vacuum-bagging, we

are able to produce everything from book-matched table tops and doors,

to complicated diamond matches and inlay on three dimensional curves

and conical shapes. Vacuum-bagging or pressing uses atmospheric

pressure to glue a veneer to a stable substrate in a urethane plastic

bag from which the air has been evacuated. We maintain an extensive

inventory of premium veneer flitches, which have been specially

selected from the thousands available to us through the local High

Point furniture suppliers market. Great care and extra time are always

taken in considering the optimal veneer figure and pattern for each

design. Samples in the actual veneer and finish are produced for

approval.

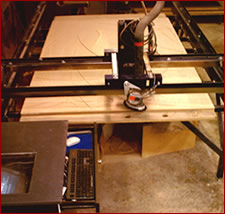

Today, our

woodworking capabilities are enhanced by our CNC router. This machine

takes our computer-drawn parts and develops perfectly matching tool

paths for a router to cut accurate templates and furniture parts. In

building a cherry

library with an eliptical plan, we used our CNC router to produce

over 75 forms that were, in turn, used to make curved moldings, doors,

and panels.

TECHNOLOGY IN FURNITURE TECHNOLOGY IN FURNITURE

As CNC machining and advanced veneering techniques have revolutionized

our furniture-making capabilities, so has our training in vigilance for

attention to detail. We are constantly researching new hardware and new

materials. Remote controlled electro-mechanical devices that open doors

on media walls, adjust the height of lecterns or expose power and

communications outlets in table tops are just a few of the many systems

we have engineered into our corporate furniture. As computers and

communications and projection applications have evolved, we have

developed better, more cost-effective ways to integrate these

technologies into the boardroom.

FINISHING FINISHING

As a custom shop, we are proficient in a wide variety of finishing

techniques. This includes simple oiled finishes, oil and NGR stains,

pigmented lacquers, clear catalyzed lacquers, catalyzed polyurethanes,

conversion varnishes, and marine paints and varnishes. Many of our

conference tables receive a beautiful rubbed finish of highly durable

European catalyzed polyurethane. A full-time specialist finishes all of

our pieces according to the requirements developed for each job. We

keep detailed records of finishing processes for every piece and have

an extensive selection of standard stain colors and integrated

finishing systems.

|