|

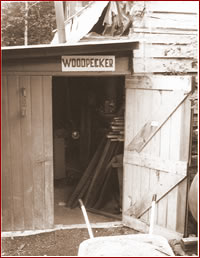

Beginnings: Lean-to shed

Ramsey Terhune

|

As you might imagine,

with a name like Woodpecker, our roots are in the woods of North

Carolina. Our first step forward was from the ankle-deep wood shavings

on a dirt-floored lean-to shed to the wide pine boards of a tobacco

storage barn, which we rescued from the flood plain of Carolina’s

Jordan Lake in the mid-70’s. At the time, we were a two-person

shop, proudly building what we called “contemporary hardwood

furniture.” Our founder was a talented and well-educated young

Englishman, Peter J. Laughton, who had taught French at Hollins

College, and Queens College. After a brief stint in law school, and as

a diversion typical of the late-60’s counterculture, he started

our business with the name Woodpecker Enterprises in January 1972

(Never mind his unfamiliarity with our American “Woody

Woodpecker” and his signature cackle). The name and the chuckles

it invokes remain 37 years later! As you might imagine,

with a name like Woodpecker, our roots are in the woods of North

Carolina. Our first step forward was from the ankle-deep wood shavings

on a dirt-floored lean-to shed to the wide pine boards of a tobacco

storage barn, which we rescued from the flood plain of Carolina’s

Jordan Lake in the mid-70’s. At the time, we were a two-person

shop, proudly building what we called “contemporary hardwood

furniture.” Our founder was a talented and well-educated young

Englishman, Peter J. Laughton, who had taught French at Hollins

College, and Queens College. After a brief stint in law school, and as

a diversion typical of the late-60’s counterculture, he started

our business with the name Woodpecker Enterprises in January 1972

(Never mind his unfamiliarity with our American “Woody

Woodpecker” and his signature cackle). The name and the chuckles

it invokes remain 37 years later!

The following fall, I joined Peter as a part

time apprentice while contemplating applications to graduate schools in

architecture. It was a good chemistry. Peter’s creativity was

enhanced by practical woodworking hand skills and training learned in

English “public schools”. I had recently graduated from

Kenyon College with a BA in sculpture and design and felt compelled to

challenge our work with a critical eye, while learning to fine-tune a

hand plane and cut dovetail joints. Always interested in things visual

and mechanical, I became increasingly focused on furniture design and

craftsmanship. Peter, on the other hand, continued his craving for new

and exciting ventures and eventually moved to Massachusetts to pursue

drawing, painting and inventing. The following fall, I joined Peter as a part

time apprentice while contemplating applications to graduate schools in

architecture. It was a good chemistry. Peter’s creativity was

enhanced by practical woodworking hand skills and training learned in

English “public schools”. I had recently graduated from

Kenyon College with a BA in sculpture and design and felt compelled to

challenge our work with a critical eye, while learning to fine-tune a

hand plane and cut dovetail joints. Always interested in things visual

and mechanical, I became increasingly focused on furniture design and

craftsmanship. Peter, on the other hand, continued his craving for new

and exciting ventures and eventually moved to Massachusetts to pursue

drawing, painting and inventing.

In 1977, I bought the business and moved it to

an abandoned fiberglass manufacturing facility that had succumbed to

the oil embargo of the early 70’s. It was a new beginning with an

enthusiastic team that had grown to five, plus a menagerie of three

dogs and a shop cat that kept us mouse-free. We suddenly had ten times

the shop space of the old barn and a thousand ideas of things we wanted

to build. I wrote a grant application to the newly formed Department of

Energy for a solar powered kiln for drying hardwoods. We didn’t

get the grant. I submitted a design for a laminated

walnut rocking chair to the prestigious Daphne Furniture Design

Competition. We didn’t get an award. But these lost opportunities

only served to sweeten other successes we were beginning to experience.

We had our first taste of the contract furniture market when we built

fixtures for the New York, Chicago and Burlington, NC showrooms of

Apparel, Inc., the maker of “Peaches & Cream”

children’s clothing. The contact had come through building

furniture for the company president, who lived in nearby Chapel Hill at

the time. With an increasing number of contract furniture jobs, we

continued making high-end residential furniture and cabinets. We

designed and built beds,

dressers,

tables,

chairs,

china

cabinets, entertainment

centers, sofas

& love seats, cradles

& high

chairs, kitchens,

spiral

staircases,

and even a small addition to a house. In 1977, I bought the business and moved it to

an abandoned fiberglass manufacturing facility that had succumbed to

the oil embargo of the early 70’s. It was a new beginning with an

enthusiastic team that had grown to five, plus a menagerie of three

dogs and a shop cat that kept us mouse-free. We suddenly had ten times

the shop space of the old barn and a thousand ideas of things we wanted

to build. I wrote a grant application to the newly formed Department of

Energy for a solar powered kiln for drying hardwoods. We didn’t

get the grant. I submitted a design for a laminated

walnut rocking chair to the prestigious Daphne Furniture Design

Competition. We didn’t get an award. But these lost opportunities

only served to sweeten other successes we were beginning to experience.

We had our first taste of the contract furniture market when we built

fixtures for the New York, Chicago and Burlington, NC showrooms of

Apparel, Inc., the maker of “Peaches & Cream”

children’s clothing. The contact had come through building

furniture for the company president, who lived in nearby Chapel Hill at

the time. With an increasing number of contract furniture jobs, we

continued making high-end residential furniture and cabinets. We

designed and built beds,

dressers,

tables,

chairs,

china

cabinets, entertainment

centers, sofas

& love seats, cradles

& high

chairs, kitchens,

spiral

staircases,

and even a small addition to a house.

By the end of the ‘80’s, we found

ourselves focused on the corporate furniture market, which best

utilized the craftsmanship and experience we had developed over the

years. In September of 1991, we had a contract with IBM to build a

series of conference tables that we had developed for them integrating

an overhead projector into the surface of the table. Their beautiful

new marketing center at Westin in Cary, NC was also to have twelve

executive briefing rooms with conference tables custom built by a

German firm. IBM had scheduled an early December opening for both an

international contingent of the World Bank and an entourage with the

Commandant of the Marine Corps. In October, IBM received a telex from

the German manufacturer stating that they would be unable to meet the

December deadline. IBM’s architect came to us with the biggest

challenge we had faced to date: could we re-engineer and produce 125 rectangular

and curved

executive briefing tables, in addition to the projector tables

already under contract, before the opening? We quickly went about

contacting our suppliers and other trusted manufacturing resources that

might be in a position to commit to IBM’s six-week deadline. We

obtained the assurances we needed, despite the holiday season, and made

our commitment to IBM. Metal legs were ordered from Italy, table

assembly hardware from Germany and a Georgia distributor, matched maple

veneer faces from High Point, and banded panel cores from Tennessee.

Two local shops helped us edge-band and sand table tops and produce

table rails, while we veneered sixty curved modesty panels in five

different radiuses. In the end, all the parts came together on time for

us to complete all the finishing in-house. IBM expressed their

gratitude to us by hosting our entire company to an elegant luncheon in

their new facility and presenting us a framed “letter

of thanks.” By the end of the ‘80’s, we found

ourselves focused on the corporate furniture market, which best

utilized the craftsmanship and experience we had developed over the

years. In September of 1991, we had a contract with IBM to build a

series of conference tables that we had developed for them integrating

an overhead projector into the surface of the table. Their beautiful

new marketing center at Westin in Cary, NC was also to have twelve

executive briefing rooms with conference tables custom built by a

German firm. IBM had scheduled an early December opening for both an

international contingent of the World Bank and an entourage with the

Commandant of the Marine Corps. In October, IBM received a telex from

the German manufacturer stating that they would be unable to meet the

December deadline. IBM’s architect came to us with the biggest

challenge we had faced to date: could we re-engineer and produce 125 rectangular

and curved

executive briefing tables, in addition to the projector tables

already under contract, before the opening? We quickly went about

contacting our suppliers and other trusted manufacturing resources that

might be in a position to commit to IBM’s six-week deadline. We

obtained the assurances we needed, despite the holiday season, and made

our commitment to IBM. Metal legs were ordered from Italy, table

assembly hardware from Germany and a Georgia distributor, matched maple

veneer faces from High Point, and banded panel cores from Tennessee.

Two local shops helped us edge-band and sand table tops and produce

table rails, while we veneered sixty curved modesty panels in five

different radiuses. In the end, all the parts came together on time for

us to complete all the finishing in-house. IBM expressed their

gratitude to us by hosting our entire company to an elegant luncheon in

their new facility and presenting us a framed “letter

of thanks.”

Today our work continues in the custom

contract furniture and architectural woodworking markets with many well

established relationships with facilities managers, designers,

architects, and contractors. Our roots in fine residential furniture

remain, as there is always an interesting piece or two in progress,

alongside the commercial projects. We welcome visitors who might want

to see what we are making and tour our shop. Our 12,000 sq. ft.

facility sits on eight acres surrounded by Jordan Lake land. Those who

stop by often comment on what an ideal workplace setting it is. We

think so, too. Please call for an appointment (1-800-359-7073). Today our work continues in the custom

contract furniture and architectural woodworking markets with many well

established relationships with facilities managers, designers,

architects, and contractors. Our roots in fine residential furniture

remain, as there is always an interesting piece or two in progress,

alongside the commercial projects. We welcome visitors who might want

to see what we are making and tour our shop. Our 12,000 sq. ft.

facility sits on eight acres surrounded by Jordan Lake land. Those who

stop by often comment on what an ideal workplace setting it is. We

think so, too. Please call for an appointment (1-800-359-7073).

|